Choosing the right dosing pump can be challenging when trying to find the solution that best fits your needs. With a wide range of dosing pumps available on the market, it can be difficult to identify the one that's right for you. The correct dosing pump must be reliable, efficient, and precise, as choosing the wrong one can cause problems with negative consequences.

In this article, we'll discuss dosing pumps and the key factors to consider when selecting the right one for your application. We'll also explain how to choose the right type of pump, flow rate, dosing percentage, and other essential factors that will help you make the right choice.

What are Dosing Pumps?

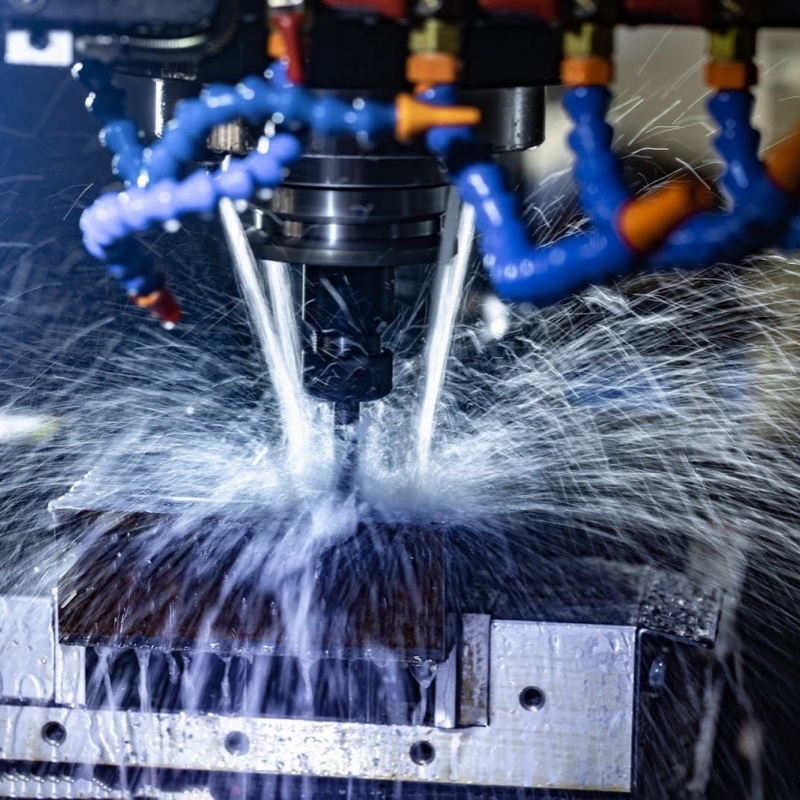

Dosing pumps are hydraulic devices directly installed on the water network that allow you to obtain a homogeneous solution always proportional to the water volume. These pumps are used in many work sectors, including:

These pumps work solely thanks to the water network's flow rate which, by activating the piston, enables liquid suction.

The liquid is automatically mixed with water at the percentage previously set by the user.

The mixed solution is then pushed out by water pressure.

Considering Flow Rate

A fundamental factor to consider when selecting the right dosing pump is the flow rate. Flow rate is the amount of incoming water that the pump can support. A dosing pump's flow rate is usually measured in:

- Liters per hour (l/h)

- Cubic meters (m³/h)

It's important to choose a dosing pump that can support the incoming water flow rate required for your application. Choosing a pump with too high or too low flow rate can cause serious problems in terms of functionality with potentially serious negative effects.

Essential Factors to Consider

Besides flow rate, there are other essential factors to consider:

- Chemical compatibility: the dosed liquids must be chemically compatible with the pump's construction materials to avoid malfunctions or worse, irreparable damage.

- Water network pressure: water pressure is fundamental for proper dosing operation; too much or too little pressure can compromise the doser's use and functionality.

- Dosing percentage: the user must choose the desired dosing percentage based on their specific application among the various available ranges.

Conclusion

Choosing the right dosing pump is essential to ensure that your application works efficiently and reliably. When selecting a dosing pump, you need to consider factors such as pump type, flow rate, dosing volume, chemical compatibility, pressure, and precision.

By considering these factors, you can choose the right pump that meets your specific needs. It's also important to regularly maintain your pump to ensure it works efficiently and reliably.

We hope this article has provided useful information about dosing pumps and how to choose the right dosing pump for your application. If you have any questions or need assistance in choosing, don't hesitate to contact us.

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application