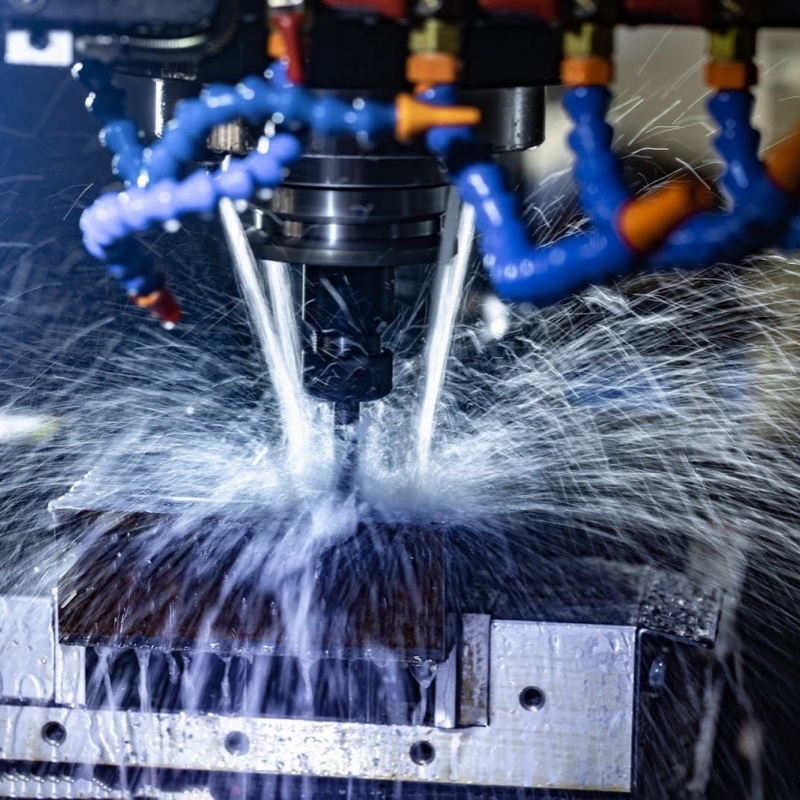

High-pressure pumps are essential tools used in many industries. They help pump high-pressure water, which is necessary for a wide range of applications, such as greenhouse misting, desalination, reverse osmosis, washing, and many others.

Introduction to high-pressure pumps

High-pressure pumps are designed to create a high-pressure fluid flow that can be used for various purposes. They can be powered by an electric motor that must be coupled with the pump.

Types of high-pressure pumps

There are two main types of high-pressure pumps: positive displacement pumps and dynamic pumps. Positive displacement pumps use reciprocating or rotary motion to move fluid through the pump. Dynamic pumps, on the other hand, use centrifugal force to move fluid through the pump.

Let's look more closely at each type of pump.

- Positive displacement pumps – Positive displacement pumps work by trapping a fixed amount of fluid and then pushing it through the pump's discharge outlet. There are two main types of positive displacement pumps: reciprocating pumps and rotary pumps.

- Reciprocating pumps – Reciprocating pumps use a reciprocating motion to move fluid through the pump. They are designed to move a fixed volume of fluid with each stroke. Reciprocating pumps are commonly used in high-pressure applications, such as oil and gas production.

- Rotary pumps – Rotary pumps use a rotary motion to move fluid through the pump. They are designed to move a fixed amount of fluid per rotation. Rotary pumps are commonly used in low-pressure applications.

- Dynamic pumps – Dynamic pumps work using a rotating propeller to create centrifugal force, which moves fluid through the pump. There are two main types of dynamic pumps: axial flow pumps and radial flow pumps.

- Axial flow pumps – Axial flow pumps use an impeller with blades that force fluid to flow parallel to the impeller axis. They are commonly used in applications where high flow rate is required, such as irrigation.

- Radial flow pumps – Radial flow pumps use an impeller with blades that force fluid to flow perpendicular to the impeller axis. They are commonly used in applications where high pressure is required, such as power generation.

How do high-pressure pumps work?

The operation of high-pressure pumps depends on the type of pump. Volumetric pumps work by trapping a fixed amount of fluid and then forcing it through the pump's discharge outlet. Dynamic pumps, instead, work using a rotating impeller to create centrifugal force, which moves fluid through the pump.

In general, high-pressure pumps work by creating pressure to move fluid from a lower pressure area to a higher pressure area. The pump draws fluid into its inlet and then moves it through the pump, where it is pressurized and then discharged through the outlet. The pressure generated by the pump is determined by the size of the impeller or piston, motor speed, and pump design.

Mixtron high-pressure pumps belong to the family of axial volumetric pumps.

Applications of high-pressure pumps

High-pressure pumps are used in a wide range of applications.

Let's take a closer look at some of these applications.

- Desalination – High-pressure pumps are used in desalination plants for converting seawater into drinking water

- Misting – High-pressure pumps are used in cooling systems for both greenhouses and animal environments to generate mist that cools the environment.

- Reverse osmosis – High-pressure pumps are used in osmosis applications to purify water. High pressure is necessary to force chemicals through the membranes.

- Washing - high-pressure pumps can be used in washing systems with numerous solutions and in numerous different applications

Conclusion

High-pressure pumps are essential components used in numerous applications.

Knowing that there are numerous types of high-pressure pumps and their application, you can choose the pump for your needs to ensure it operates effectively and efficiently.

The Mixtron pump is an axial piston pump that requires an electric motor to be coupled in order to function.

It works with water and has the particularity, given the unique materials with which it is produced, of significantly resisting seawater corrosion.

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application