Technologies and strategies for effective and safe purification

High-quality water is an essential resource for public health and numerous industrial processes. Ensuring that the water that reaches our homes or is used in various sectors is safe and purified is a complex task that requires the application of advanced technologies. Among these, the precise dosing of chemical reagents and disinfectants plays an essential role, and optimal control of this process not only ensures the potability of the water but also improves treatment efficiency, reducing waste and optimising operating costs.

But what are the most effective technologies and strategies for achieving optimal dosing in water treatment and purification? Let's find out how modern systems can make a difference.

Chlorine dosing systems: effectiveness and safety

Chlorine is one of the most widely used disinfectants globally for water purification, thanks to its effectiveness in eliminating bacteria, viruses and other pathogenic microorganisms. However, its effectiveness is closely linked to precise and controlled dosing; overdosing can generate unwanted by-products and alter the taste of the water, while underdosing compromises its safety.

Modern chlorine dosing systems are designed specifically to ensure proportional and automated injection of the disinfectant. These systems often include precision dosing pumps, sensors for continuous monitoring of residual chlorine, and intelligent control units, with the aim of maintaining a constant and optimal level of disinfection that can adapt in real time to changes in raw water quality and demand.

The adoption of these technologies not only increases the safety of treated water, but also helps to optimise chlorine consumption, leading to significant savings and more sustainable resource management.

Dosing regulators for waterworks: precision at the service of the community

Waterworks management requires the utmost attention to the quality and safety of the water distributed. Dosing regulators for waterworks are essential tools in this context, as they allow for the automation and optimisation of the addition of all the chemicals necessary for purification. In particular, these advanced systems are not limited to injecting fixed quantities of reagents, but are also able to adapt the dosage according to specific water parameters, such as pH, turbidity, conductivity or residual chlorine.

Thanks to the integration of in-line sensors and sophisticated control software, the regulators ensure that every litre of water flowing through the aqueduct receives the appropriate treatment, which means not only safer water for consumers, but also reduced reagent waste and greater operational efficiency for the managing bodies. Their ability to react quickly to changes in water conditions ensures constant protection against potential contamination, making them essential for public health.

Mixing systems for drinking water treatment: homogeneity and effectiveness

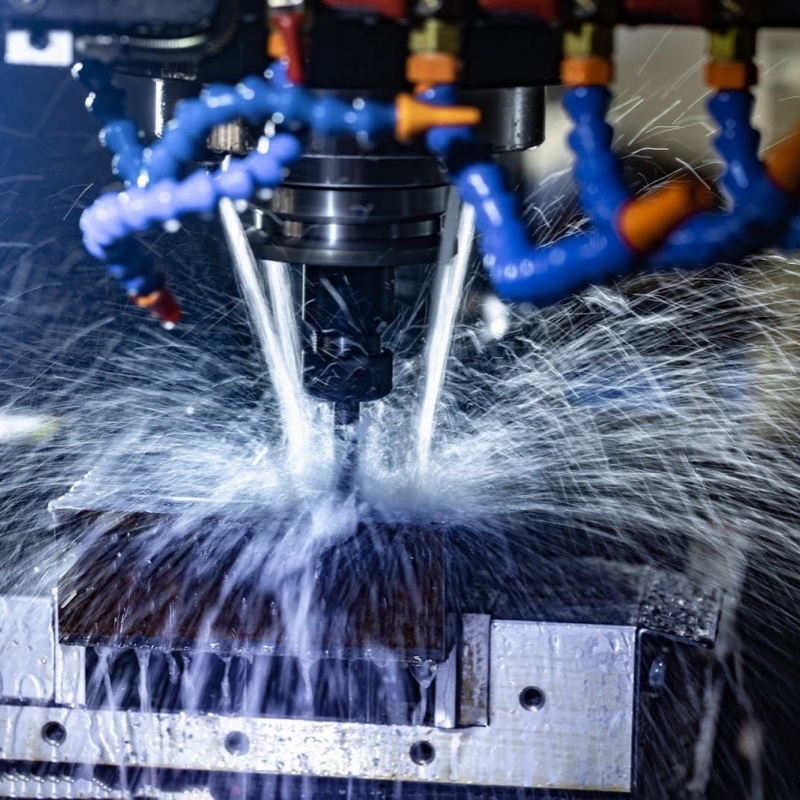

In addition to precise dosing, optimal mixing of chemical reagents in water is a critical step in the drinking water treatment process. Homogeneous distribution of the products ensures that every particle of water comes into contact with the disinfectant or flocculant, maximising the effectiveness of the treatment. Water purification mixing systems are designed precisely for this purpose: they use different technologies to ensure that the reagents disperse quickly and evenly throughout the water.

These systems include static mixers, which use water flow to create turbulence, and dynamic mixers, which use mechanical agitators to promote dispersion. The choice of the most suitable system depends on factors such as the type of reagent, the water flow rate and the characteristics of the plant.

Effective mixing reduces the contact time required for the reaction, optimises the use of chemicals and prevents the formation of areas with uneven concentrations, which could compromise the final water quality. This integrated approach to dosing and mixing is essential for achieving the best results in water treatment.

Chemical parameter control in water: continuous monitoring for quality

Controlling chemical parameters in water is the basis for any effective treatment system; without constant and accurate monitoring, it would be impossible to correctly adjust reagent dosages and guarantee the final water quality. Today, modern plants use a wide range of sensors and in-line analysers capable of detecting essential parameters such as pH, residual chlorine, turbidity, dissolved oxygen and conductivity in real time.

This data is transmitted to automated control systems which, based on predefined algorithms, can precisely adjust the dosing pumps and mixing systems. Thanks to this approach, any anomalies can be immediately identified and corrected, preventing quality issues and ensuring that the water consistently complies with regulatory standards.

Investing in advanced monitoring and control technologies is not just a matter of compliance, but represents a fundamental step towards more efficient, safe and sustainable water management.

Trust Mixtron for optimal dosing in water treatment plants

Ensuring superior water quality through precise and controlled dosing is one of Mixtron's missions. Our cutting-edge solutions are designed to improve every stage of water treatment, from chlorine injection to chemical parameter management, ensuring maximum efficiency and safety.

In particular, with Mixtron's dosing pumps and high-pressure pumps, you are choosing excellence and innovation for your systems, without compromising on sustainability, reliability and safety. Contact us and request a quote!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application