Optimise purification with advanced dosing and pressure control solutions

Reverse osmosis (RO) is a cutting-edge water purification technology that is essential in countless industries. From treating brackish water to make it drinkable to producing ultrapure water for the pharmaceutical and electronics industries, its ability to remove impurities, dissolved salts, heavy metals and microorganisms is unrivalled.

The heart of these systems consists of semi-permeable membranes capable of selectively filtering out unwanted substances; however, the mere presence of these membranes is not enough to guarantee optimal and long-lasting performance. To maximise the efficiency of reverse osmosis systems and significantly extend their useful life, two factors are absolutely crucial: extremely precise dosing of specific chemical additives and rigorous, dynamic control of operating pressure.

Careful management of these parameters prevents harmful phenomena such as fouling and scaling of the membranes, which can irreversibly compromise their performance, reducing productivity and increasing maintenance costs. As a result, energy consumption is also optimised and consistent, reliable purified water quality is ensured.

But what are the most advanced technological solutions and operational strategies that enable this level of precision to be achieved and maximise the overall efficiency of reverse osmosis plants? Let's explore in detail how modern systems can make a difference in this highly specific and delicate field.

Dosing systems for active membrane protection

Within a reverse osmosis plant, the pre-treatment phase is of essential importance. It is in this initial phase, in fact, that the foundations are laid for protecting the delicate RO membranes from potential threats such as scaling, chemical degradation and microbiological growth. Filtration dosing systems are the tools used to precisely inject essential additives, such as anti-scaling agents, which are indispensable for preventing the precipitation of mineral salts (such as calcium carbonate and barium sulphate) that could form an insulating layer on the surface of the membranes, reducing their permeability. Biocides are also important, particularly for controlling the proliferation of biofilm and bacteria that can clog membranes, as are chlorine reduction agents (such as sodium metabisulphite), which neutralise residual chlorine in the feed water that can irreversibly damage polyamide membranes, compromising their selectivity.

Precision in the dosage of these chemicals is non-negotiable: insufficient dosage would fail to effectively prevent fouling, leading to reduced plant performance and more frequent costly chemical washings; conversely, excess chemicals would not only unnecessarily increase operating costs, but could also affect the quality of the treated water.

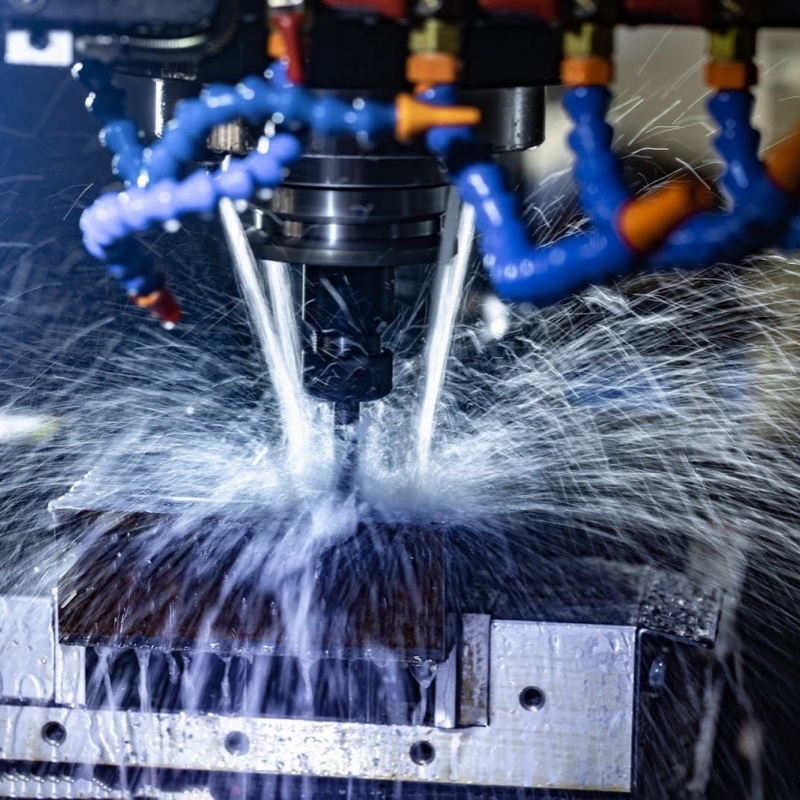

The most modern reverse osmosis dosing systems use proportional volumetric dosing pumps, capable of dispensing minimal and precise quantities of liquid. These pumps are often integrated with flow sensors that monitor the volume of incoming water in real time and with sophisticated automatic control systems that adjust the pump flow rate accordingly. This allows for continuous and proportionate injection of the reagent, which dynamically adapts to changes in the flow rate of the raw water or its composition.

The implementation of these targeted technologies ensures that the membranes always operate under ideal conditions, maximising filtration efficiency and significantly extending the useful life of the membranes, with considerable economic and operational benefits.

Pressure control for osmosis: the delicate balance for performance

Operating pressure is the driving factor behind every reverse osmosis system and directly influences both production efficiency and membrane longevity. Too low a pressure results in reduced permeate production (purified water) and lower efficiency in removing dissolved salts, making the system less productive and less effective. On the other hand, excessive pressure can cause much more serious consequences, such as mechanical stress and irreversible damage to the membranes, accelerating their degradation and drastically reducing their useful life. Furthermore, operating at higher pressures than necessary leads to a significant increase in energy consumption, negatively affecting operating costs. For all these reasons, accurate, constant and dynamic osmosis pressure control is absolutely essential.

This control can be performed using high-pressure pumps specifically designed for reverse osmosis applications, the beating heart of the system, supported by control valves and a network of pressure sensors strategically positioned along the water path. Specifically, intelligent controllers, often based on PLCs or microprocessors, constantly monitor the data coming from the sensors: based on predefined algorithms and real-time feedback, they automatically adjust the speed of the pumps (via inverters) or the opening of the valves to maintain the pressure at exactly the optimum value for the current operating conditions.

This system not only guarantees constant production of purified water of the desired quality, but also contributes significantly to extending the useful life of the membranes, reducing the mechanical stress to which they are subjected and preventing compaction or breakage. A reverse osmosis plant with a well-calibrated pressure control system can perfectly balance production efficiency with membrane preservation, leading to significant long-term savings in terms of energy and component replacement costs.

Dosing units for water systems: multifunctional integration and operational flexibility

In many cases, reverse osmosis plants are not isolated entities, but key components within larger and more complex water treatment systems. In this context, dosing units for water systems play a crucial role: they are not limited to injecting additives in the RO pre-treatment phase, but allow for the smooth integration and precise dosing of a variety of chemicals in different sections of the entire water cycle. Their versatility makes them suitable for multiple applications: they can be used for dosing flocculants or coagulants in the clarification phase, for injecting pH neutralisers (both acidic and basic) to optimise the pH of the water at various stages of the process, or for adding disinfectants in the post-RO phase to ensure the microbiological safety of the purified water before its distribution or final use.

The most modern dosing units are designed for maximum operational flexibility and can handle a wide range of flow rates and reagent concentrations, adapting to different plant requirements. The use of high-precision dosing pumps, combined with advanced control systems (which may include pH, ORP or conductivity sensors), ensures that the amount of additive injected is always proportional to the water flow or the specific parameters to be controlled.

Thanks to this level of control, it is possible not only to optimise the overall efficiency of the water treatment plant as a whole, but also to contribute to a significant reduction in the consumption of chemicals, minimising environmental impact and containing operating costs.

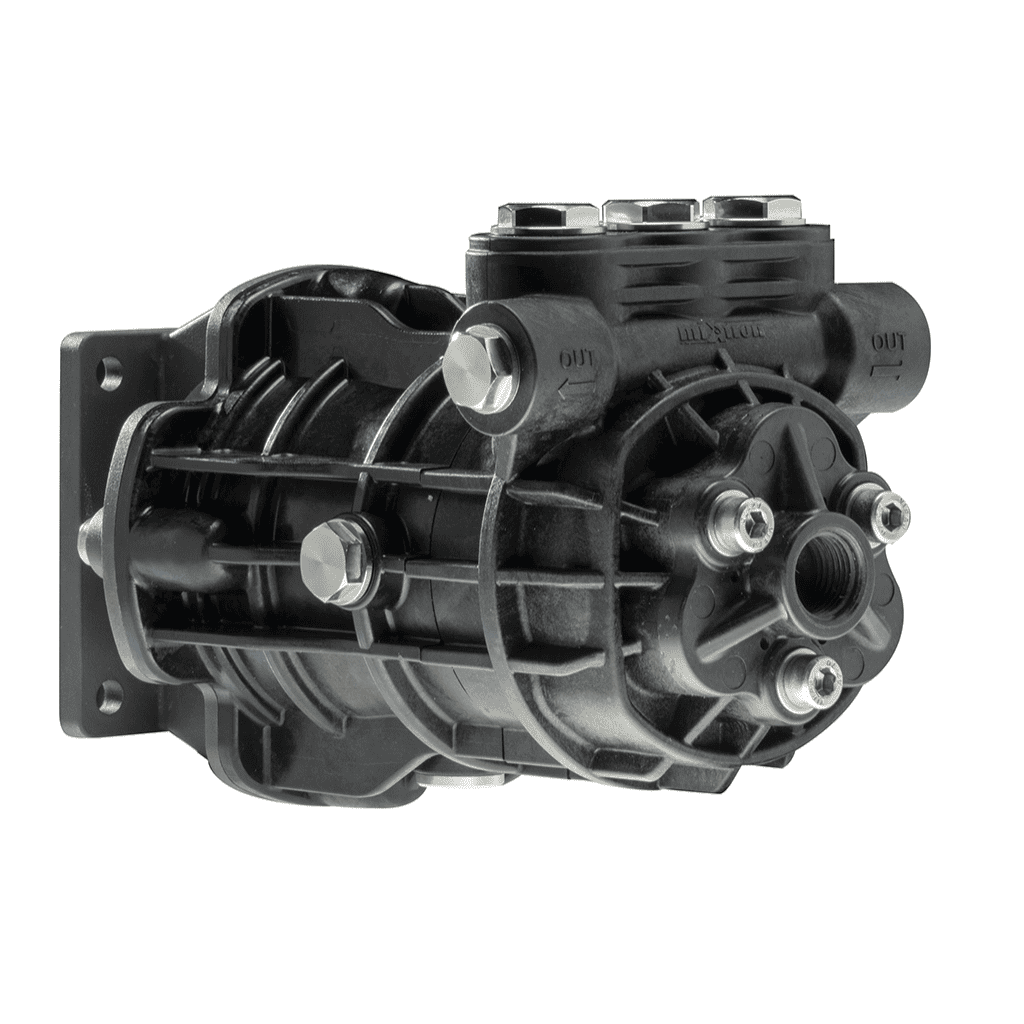

Choose Mixtron pumps to maximise the overall efficiency of reverse osmosis plants

In the field of reverse osmosis, precision is synonymous with efficiency, reliability and sustainability. Ensuring superior quality purified water and extending the life of your systems requires solutions that combine cutting-edge technology and in-depth knowledge of processes, and Mixtron is the ideal supplier to achieve these goals.

Our dosing pumps and high-pressure pumps are designed to offer the accuracy and reliability needed for optimal dosing of all additives, from membrane protection to management of key parameters at every stage of the process.

With Mixtron, you are guaranteed precise and consistent dosing, as well as robust and easy-to-maintain systems designed to maximise uptime and minimise waste. Our technologies enable you to ensure impeccable purified water quality, longer filter membrane life and unprecedented operational efficiency, resulting in a significant return on investment and more sustainable management of your water resources.

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application