Nowadays, corporate sustainability is no longer just an ethical issue, but a strategic imperative that directly affects competitiveness and profitability. The fundamental pillars of this sustainability include energy efficiency and reduced consumption in all production processes, and in this context, dosing systems play a decisive role. Although they may seem like minor components, their optimized management can lead to significant energy savings, lower operating costs, and a significantly reduced environmental impact.

Let's take a closer look at how intelligent dosing management can make a difference, discovering how modern dosing systems can tangibly improve a company's sustainability and which technologies and strategies can optimize energy efficiency and reduce costs, transforming a potential point of consumption into an opportunity for sustainable improvement.

Reducing your energy footprint with efficient dosing systems

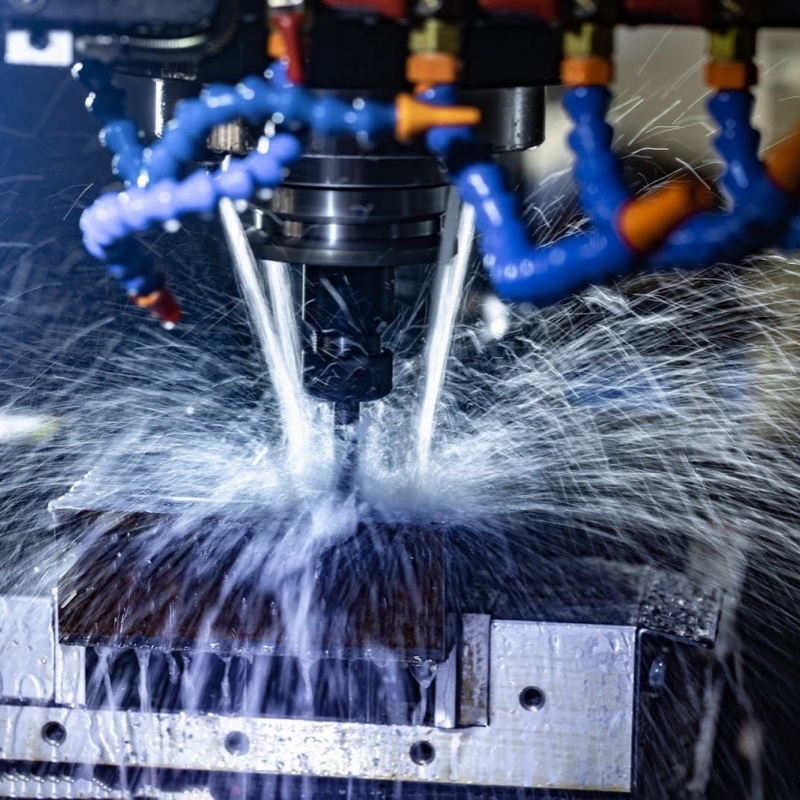

Energy management in industrial plants is a vast field, but every component, even the smallest, contributes to overall consumption. Dosing systems, if not chosen or managed correctly, can be an unexpected source of energy waste. A system that doses more product than necessary or operates with mechanical inefficiencies are all factors that translate into higher energy consumption and, consequently, higher operating costs and a larger carbon footprint.

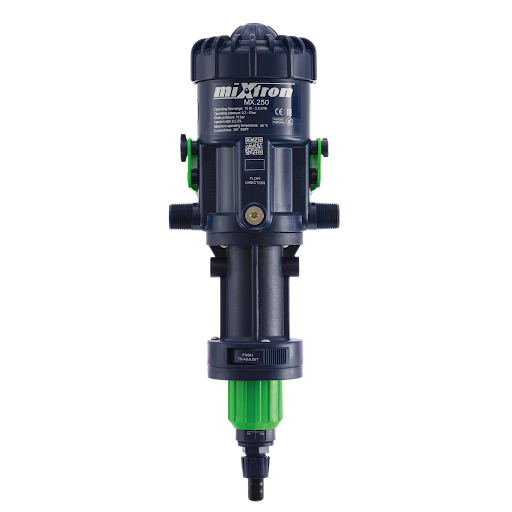

On the contrary, adopting efficient dosing systems allows energy consumption to be optimized. Mixtron proportional volumetric pumps, for example, operate without electricity, exploiting the pressure of the water flow and completely eliminating the energy consumption associated with dosing.

State-of-the-art dosing systems for sustainable raw material management

Reducing consumption in dosing systems goes far beyond energy savings alone, extending to the consumption of the fluids themselves, whether they are chemicals, water, or lubricants. Inaccurate or excessive dosing leads to a direct waste of raw materials, which translates into higher purchase and disposal costs. In many sectors, such as professional cleaning, water treatment, or agriculture, even small percentages of overdosing, when multiplied by large volumes, can generate considerable economic losses over time.

Modern dosing systems are designed to minimize this waste through millimeter precision in dispensing. Volumetric dosing pumps ensure that the amount of product dispensed is exactly what is required, without excess.

Reducing consumption is not only an economic advantage, but also an environmental one: less product used means fewer natural resources extracted, less energy for production and transport, and less waste to dispose of. This circular approach is a key element of corporate sustainability, demonstrating a concrete commitment to more responsible operating practices.

The key role of electronic control

Electronic control for fluid efficiency represents the most advanced level of optimization in dosing and pumping systems. Through the integration of sensors, PLCs (Programmable Logic Controllers), and management software, it is possible to monitor vital parameters such as flow, pressure, fluid concentration, and even water quality in real time. This constant flow of data allows the system to dynamically adjust the dosing and performance of the pumps, ensuring that fluids are managed with the highest possible efficiency.

For example, in a water treatment system, sensors can detect changes in raw water quality and electronic controls can automatically adjust the dosage of coagulants or disinfectants to maintain desired standards, avoiding overdoses. In a centralized lubrication system, on the other hand, pressure and flow monitoring can indicate anomalies or leaks, allowing timely intervention to prevent lubricant waste and damage to machinery.

The automation provided by electronic control reduces dependence on human intervention, minimizing dosing errors and ensuring greater consistency in processes. This not only translates into reduced fluid and energy consumption, but also greater process stability, improved final product quality, and reduced downtime for maintenance. Electronic control is, therefore, an enabling factor for more sustainable and efficient operations, offering visibility and the ability to intervene immediately in fluid management processes.

Mixtron: your partner for corporate sustainability

The pursuit of corporate sustainability necessarily involves the optimization of every single process, and fluid management is no exception. When designed and implemented correctly, dosing systems can become valuable allies in achieving energy efficiency and reducing operating costs. Mixtron is at the forefront of this sector, offering solutions that combine innovation and environmental responsibility.

Our dosing pumps are the result of continuous research aimed at maximizing efficiency and reducing waste. Whether you need to dose fluids for industrial processes, manage machine lubrication, or optimize professional cleaning, Mixtron solutions allow you to achieve precise fluid control while minimizing energy and product consumption. This translates into tangible benefits: lower operating costs, a reduced environmental footprint, and a concrete contribution to the reputation of a company committed to sustainability.

Want to make your processes more efficient and sustainable? Contact us for a personalized consultation!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application