In modern livestock farming, managing animal health is closely linked to the efficiency of systems and the ability to intervene in a practical and organised manner in daily routines. In particular, the administration of medicines, additives or functional solutions through drinking water is an increasingly widespread practice, especially in contexts where it is necessary to manage a large number of animals. In this scenario, dosing pumps are tools designed to support farmers in the management of treatments through water, integrating into existing processes in stables and distribution systems.

With this article, we at Mixtron want to offer a detailed overview of these solutions, analysing their role in livestock farming and the main aspects to consider.

The challenges of treating livestock in zootechnical contexts

In modern livestock farming, treating animals is a complex challenge, especially when working in high-density environments. The need to treat a large number of animals makes it difficult to rely on manual interventions or poorly structured solutions, which risk being ineffective or difficult to manage over time. Another critical issue concerns the continuity of daily operations in the barn: medication must be integrated without interfering with normal farm activities, avoiding downtime or complex procedures. In addition, farmers often have to adapt to changing needs related to specific stages of the production cycle, preventive treatments or targeted interventions in case of health issues.

In this context, it is essential to have systems that allow medication to be managed in an organised manner that is compatible with existing facilities, meeting the operational needs of modern farms without increasing management complexity.

Why are dosing pumps essential for livestock medication?

On farms where medication is administered through drinking water, it is essential to have solutions specifically designed to manage the addition of medicines, supplements or other liquid products in a way that is functional to the organisation of the barn. Dosing pumps meet this need, supporting farmers in managing treatments without changing established operating habits.

These devices are widely used, especially in poultry and pig farms, where the large number of animals requires a centralised system for administering treatments. In addition to medication, dosing pumps are also used for water acidification, with the aim of promoting proper hygiene and animal welfare management.

The advantages of proportional dosing pumps for livestock medication

Thanks to the proportional volumetric dosing device, farmers can manage their animals' health with greater peace of mind. This type of solution allows the flow of water to be accompanied by a quantity of product dosed in line with the farm's needs, adapting to the different operational phases and treatments required.

The use of proportional dosing pumps also reduces the need for manual intervention and simplifies the daily management of medication, integrating naturally into the watering systems already present in the barn.

How to integrate dosing pumps into existing watering systems

One of the most appreciated aspects of dosing pumps for livestock medication is their ease of integration into existing drinking systems in the barn. In many cases, in fact, no invasive work on the structure of the system is necessary: the dosing pump connects directly to the plumbing system, becoming part of the water distribution circuit. This installation method allows farmers to adopt a medication solution without having to redesign the existing system or interrupt daily activities for long periods of time. Dosing pumps can be installed at strategic points in the watering line, ensuring practical management of treatments and easy accessibility for routine inspection and maintenance operations.

The simplicity of installation makes these solutions suitable for both new facilities and existing stables, offering a high level of flexibility and allowing them to meet the specific needs of each farm.

Technical characteristics to consider in a dosing pump for livestock medication

The choice of a dosing pump for livestock medication depends on several factors related to the farm, the watering system and the type of treatment to be carried out. There is no single solution that is valid for all contexts: each installation has specific requirements that must be carefully evaluated.

The main technical characteristics to consider include water flow rate, which must be adequate for the size of the farm, the dosage range, which is necessary for the correct administration of medicines or acidifiers, and the working pressure of the system, which must be compatible with the operating conditions of the barn. The construction materials also play an important role, especially in terms of durability and reliability.

For example, in poultry or pig farms with a large number of animals, where the performance of the system directly affects the efficiency of medication, it may be necessary to use a dosing pump capable of working at flow rates of around 2,500 litres per hour and with an adjustable dosage between 0.2% and 2%, so as to adapt to the different stages of treatment without requiring modifications to the existing system. However, depending on the type of product to be diluted, models with different dosing ratios are also commonly used, for example between 1% and 5% or between 0.5% and 4%.

Mixtron's contribution to improving livestock medication in breeding facilities

In a context as complex as that of modern livestock farming, where the efficiency of watering systems and the correct management of medication play a central role, relying on solutions designed specifically for the livestock sector is essential. Mixtron has been working for years on the development of proportional dosing pumps designed to integrate into existing systems and support farmers in the daily management of water-based treatments. Mixtron solutions stand out for their user-friendly approach, long-term reliability and ability to adapt to different installations and operational needs, meeting the typical requirements of poultry and pig farms, but not only.

Even in the most delicate stages of the breeding cycle, such as those immediately following the birth of livestock, dosing accuracy takes on an even more critical role. Mixtron dosing units are designed to ensure accurate mixing of water and additives even at very low flow rates, operating reliably even below 10 litres per hour. This feature allows for controlled and continuous medication management even in the early stages of rearing, without compromising the efficiency of the watering system.

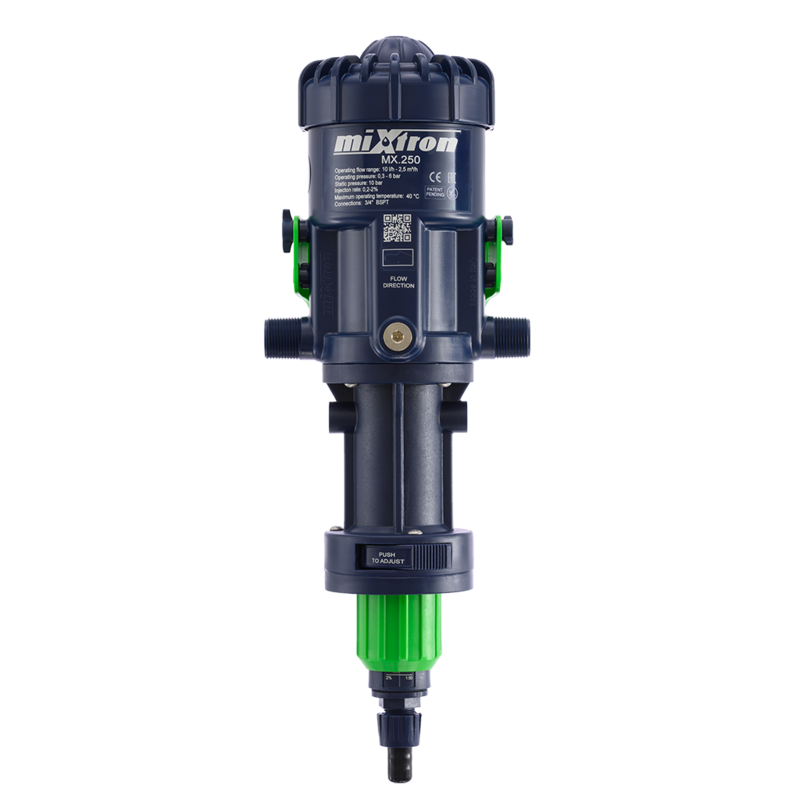

MX.250.P022: the most popular model on farms

One of the most widely used Mixtron solutions is the MX.250.P022 model, a proportional volumetric dosing pump that does not require a power supply and uses the water flow directly to dose the additive. This makes it particularly suitable for drinking systems in livestock housing, where simplicity and operational continuity are essential.

The MX.250.P022 dosing pump is designed to operate at flow rates of up to 2,500 litres per hour and offers adjustable dosing between 0.2% and 2%, features that allow it to be used in various stages of medication and treatment. The dosing pump operates at a working pressure of between 0.3 and 6 bar, with a maximum static pressure of 10 bar, making it compatible with the typical conditions of drinking systems on livestock farms. From a construction point of view, the use of AISI 316 and Duplex metal components, combined with high-performance technopolymers and various seal options (Viton, EPDM and reinforced variants), helps to ensure strength, reliability and long life even under continuous use.

Trust in the experience and quality of Mixtron products

Medicating livestock through drinking water is now an established practice in modern farms, especially those with large numbers of animals and highly automated processes. In this scenario, having reliable, easy-to-integrate solutions designed specifically for the livestock sector is crucial for the efficient management of facilities and daily activities in the barn. Thanks to its extensive experience in the field of proportional dosing pumps, Mixtron supports farmers and operators in the sector with solutions designed to meet different operational needs, guaranteeing build quality, application versatility and qualified technical support.

For further information or to find the most suitable solution for your facility, contact the Mixtron team and rely on the support of professionals with experience in the livestock medication sector.

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application