Production 4.0 with Mixtron's test bench

At the core of Mixtron's philosophy is the idea that every solution stems from your specific needs. Our entire production process is built around this concept: we listen, analyse and produce products that not only meet your requirements, but also exceed our standards. In order to produce ever more complete solutions, we have set up a test bench. For us, this is no mere test site, but rather the heartbeat of our innovation: here, advanced technology and automation merge with the precision of Italian craftsmanship to create a tailor-made test bench, built from scratch for each project. This high-tech, fully automated laboratory is the strength of our production 4.0, where each pump is created to meet superior quality and performance standards.

Production 4.0 with Mixtron's test bench

Stage 1 -

Selection of components

Our components, lined up, are scanned and selected by our laser robots to ensure perfect process reiteration.

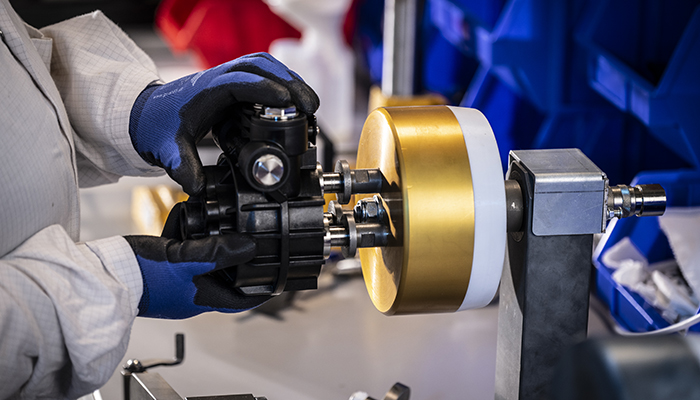

Stage 2 -

Our Conformity Tests

Each item is subjected to strict tests to ensure its perfect conformity.

Stage 3 -

Automated Assembly

Assembly takes place with millimetric precision thanks to an automated process assisted by our operators.

Stage 4 -

Multistation Final Test

Each pump undergoes three types of tests:

- Air control test

- Seals control test

- Multistation final test