A comparison of volumetric and proportional systems for dosing chemical additives, detergents and reagents in water treatment

The dosing of chemical additives, detergents and reagents in water treatment is a very delicate phase, because it must guarantee efficiency and safety in industrial processes. Choosing the correct dosing system between proportional and volumetric technology is therefore crucial to optimise product consumption and ensure consistent results over time.

In order to make the best decision, one needs to analyse the features of both solutions and compare the advantages and practical applications in order to identify the technology best suited to one's needs.

Volumetric dosing: features and advantages

The volumetric dosing system is based on dispensing a fixed volume of additive per operating cycle. This method is ideal in all applications that require the maintenance of a precise and constant amount of product, regardless of water flow variations. In fact, volumetric dispensers operate by means of mechanical or electronic dosing pumps, which take the product from a tank and feed it into the hydraulic circuit.

The main advantages of volumetric dosing are as follows:

- has high accuracy: the volume of dosed additive is constant and is not affected by variations in water flow rate;

- is independent of flow fluctuations: based on a fixed dosing principle, the system is not affected by variations in the flow rate of the main liquid;

- is easy to calibrate: the amount of product to be dosed can be precisely set, which ensures repeatability and stability in the process;

- ensures operational reliability: due to its very simple design, volumetric dosing requires less maintenance than other technologies.

That said, it should be noted that volumetric dosing may have certain limitations, particularly in environments where the water flow rate varies frequently; in these cases, constant monitoring is necessary to avoid over- or under-dosing.

Proportional dosing: features and advantages

Proportional dosing is a system for adjusting the amount of additive according to the water flow rate. The method uses mechanical or electronic devices to measure the water flow and automatically adjust the amount of product to be dosed, ensuring constant proportionality between the liquid to be treated and the additive injected.

Consequently, the advantages that proportional dosing can offer include:

- great adaptability to flow rate variations: automatic adjustment allows a constant ratio between water flow and dosed additive to be maintained;

- less risk of wastage: by avoiding over- or under-dosage, this system allows more efficient use of chemicals, reducing operating costs and environmental impact;

- greater homogeneity in treatment: chemical distribution is uniform throughout the water flow, which avoids excessive or ineffective concentrations;

- advanced automation: proportional systems can be integrated with sensors and control instruments to further optimise the dosing process.

A possible disadvantage of proportional dosing is the need for more sophisticated components than volumetric dosing units, which can result in more complex maintenance and a higher initial cost.

Volumetric and proportional dosing: the differences

In order to better understand the differences between volumetric dosing and proportional dosing, a comparison of their respective characteristics can be very useful, especially when making a choice based on the final application and the required operating parameters.

Here is a comparative analysis of the main factors to consider:

| Factor | Volumetric dosing | Proportional dosing |

| Accuracy | High, but fixed | High and adaptable |

| Adaptability to flow rate variations | Limited | Optimal |

| Efficiency in the use of additives | Less efficient in the case of variable flows | Maximum efficiency |

| Maintenance | Reduced | Greater, but with automation possibilities |

| Operating costs | Lower | Optimised in the long term |

By taking these peculiarities into account, it is possible to make a more informed and, above all, targeted choice.

Volumetric and proportional dosing: practical applications

Both volumetric dosing and proportional dosing are used in numerous, highly variable sectors. The main ones are:

Industry and water treatment

In industrial and municipal water treatment, proportional dosing is often the primary choice due to its ability to adapt to variable flows and ensure precise and optimised dosing of chemical reagents. However, in processes where the water flow is constant and predictable, volumetric dosing may be a more reliable and less complex solution.

Agriculture and irrigation

In irrigation and fertigation, proportional dosing is particularly advantageous, as it allows a constant concentration of fertilisers and additives to be maintained irrespective of changes in water flow rate.

Health and food sector

In the food and pharmaceutical sector, where dosing accuracy is crucial for the safety and quality of the end product, the choice between volumetric and proportional dosing depends on the specific application. To give an example: in process water disinfection processes, proportional dosing ensures constant disinfectant delivery, while in pre-dosed mixing applications, volumetric dosing may be sufficient.

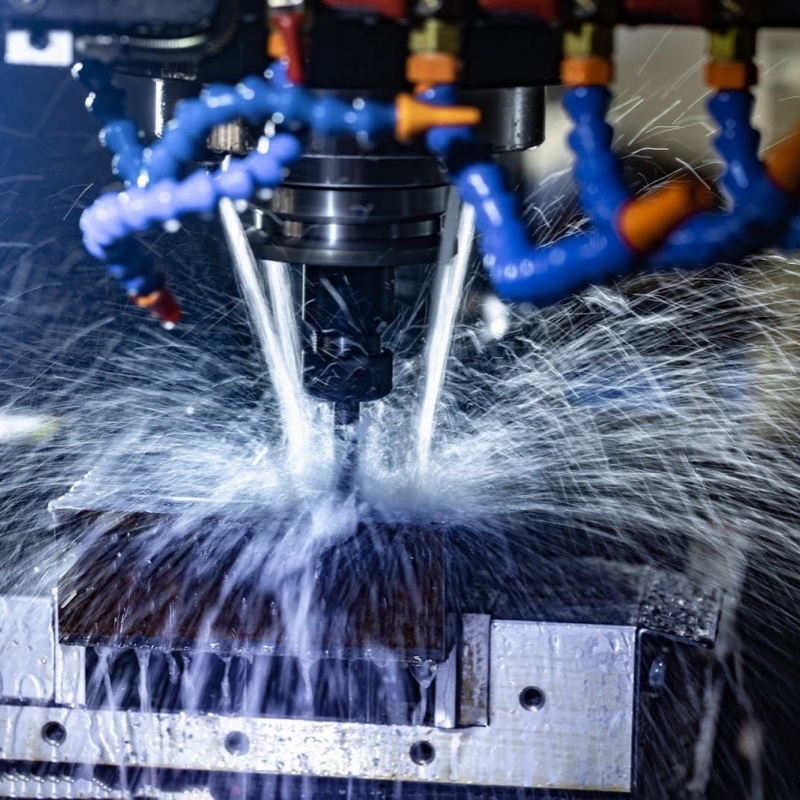

Metalworking sector

In the metalworking industry, dosing emulsifiers for the preparation of lubricating oils used in iron-cutting processes plays a crucial role in ensuring efficiency and durability. In applications where flow conditions are stable, volumetric dosing is a reliable choice, ensuring precise and repeatable quantities of emulsion. However, in systems characterised by variations in flow rate or lubricant demand, proportional dosing allows dosing to be automatically adapted to the quantity of fluid in circulation, optimising mixing and improving lubrication quality. Both systems, when properly calibrated, help reduce tool wear and maintain consistent process performance.

How to choose between volumetric and proportional dosing?

To choose the most suitable technology between a volumetric doser and a proportional doser, it is important to consider the following aspects:

- the variation in water flow rate: if the flow rate is constant, volumetric dosing can be an effective solution; if not, proportional dosing is more suitable;

- the required accuracy: proportional dosing ensures more accurate control in applications where a constant concentration is required;

- operational efficiency: proportional dosing reduces the risk of wastage and optimises the consumption of chemical additives;

- installation and maintenance costs: volumetric dosing has lower initial costs, while proportional dosing requires a higher initial investment but can lead to savings in the long run due to higher efficiency.

Choose Mixtron for an accurate and reliable dosing system

If you want to optimise the dosing of chemical additives in water treatment, Mixtron offers dosing solutions designed for precision, efficiency and reliability.

Thanks to its long experience in the industry, Mixtron can provide you with customised technical support and help you choose the most suitable system for your needs. Contact us today to request a no-obligation quote!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application