The best dosing pumps to guarantee safety, quality, and compliance with current regulations

In the food industry, sanitization is an aspect that requires particular attention to ensure product safety and compliance with current health and hygiene regulations. The food industry is, in fact, regulated by strict safety and hygiene rules, and all tools and machinery used must comply with standards such as:

- HACCP (Hazard Analysis and Critical Control Points), which guarantees food safety;

- European regulations on equipment that comes into contact with food;

- ISO certifications specific to the sector.

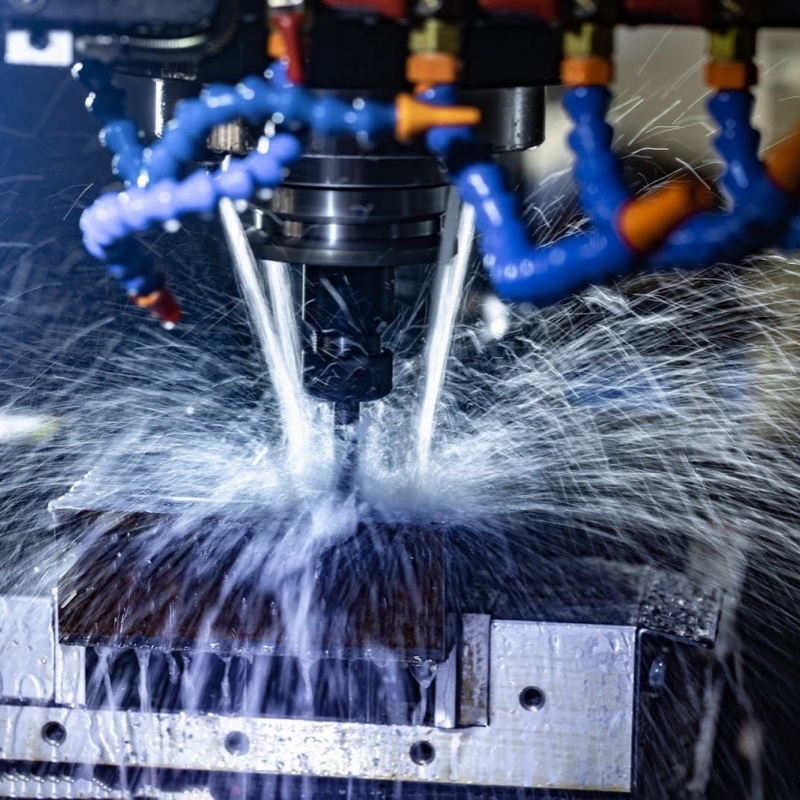

In order to comply with regulations and guarantee compliance, the use of dosing pumps for detergents, additives, and ingredients is essential, as it allows for the optimization of cleaning and production processes, ensuring precision and efficiency.

But which dosing device should you choose to get the best results? Let's analyze the different types of dosing pumps, how they work, and the criteria for selecting the solution best suited to the needs of the food industry.

Food sanitization and dosing devices: what is the connection?

The food industry operates in a highly regulated environment, where safety and hygiene are key factors. The sanitization of equipment and work surfaces therefore requires the use of specific detergents and disinfectants, which must be dosed precisely to avoid contamination, unwanted residues, or product waste.

For this reason, the use of automated dosing pumps is highly recommended, as they offer a number of advantages:

- dosing accuracy: they guarantee the correct concentration of detergents and disinfectants;

- waste reduction: they prevent excessive consumption of chemicals, thereby reducing operating costs;

- operator safety: minimizes direct contact with potentially hazardous chemicals;

- regulatory compliance: ensures that the sanitization process complies with food safety standards;

- operational efficiency: simplifies and speeds up cleaning operations, reducing machine downtime.

Dosing pumps for the food industry: types

There are several types of dosing pumps that can be used in the food industry, each with specific characteristics that determine their suitability for a given application. The main ones are:

- volumetric dosing pumps, which measure the volume of liquid dispensed. They are used to ensure uniform distribution of detergents and additives and reduce the risk of over- or under-dosing. They are ideal for processes that require constant precision;

- proportional dosing pumps, which automatically regulate the amount of detergent or additive based on the water flow, ensuring precise and constant dosing regardless of pressure or flow rate variations. They are particularly suitable for automated sanitization systems where it is essential to maintain a stable concentration of chemicals;

- peristaltic pumps, which use a roller compression system to push the liquid through a flexible tube. The main advantage is that there is no contact between the liquid and the mechanical components of the pump, which reduces the risk of contamination and facilitates cleaning. They are suitable for dosing additives and sensitive substances;

- electronic dosing devices, which offer advanced control over fluid management because they allow precise programming of dosing parameters via digital interfaces. These devices are ideal for applications where dynamic adjustment of dispensed quantities is required based on real-time data.

How to choose the best dosing pump for the food industry?

The choice of the most suitable dosing pump for the food industry depends on several factors, which must be carefully analyzed in advance in order to select the most efficient model. The characteristics to be taken into account are:

- the type of substance to be dosed, because each type requires different dosing devices. For example, detergents and disinfectants require dosing devices that can handle chemicals, are corrosion-resistant, and are easy to clean, while flavorings and additives require high-precision dosing devices that prevent alterations in the quality of the final product. For liquid ingredients, on the other hand, it is necessary to choose hygienic systems made of materials suitable for contact with food;

- accuracy, because some applications require precise dosing. In these cases, electronic and proportional dosing pumps are the best choice; however, if real-time control is not required, volumetric dosing pumps are also perfectly adequate.

- compatibility with the existing system, i.e., with the production or sanitation plant already in use. In particular, it is necessary to assess the ease of integration with existing pipes and delivery systems, the construction materials to avoid unwanted chemical reactions, and maintenance requirements to ensure operational continuity and reduce downtime.

Mixtron: solutions for food sanitization

A benchmark in the production of advanced dosing pumps for the food industry, Mixtron offers solutions designed to guarantee precision, safety, and efficiency. The dosing systems available are ideal for sanitizing production plants, bottling lines, and work surfaces, guaranteeing:

- Proportional dosing without waste, as they automatically adjust the amount of detergent based on the water flow, reducing consumption and optimizing costs.

- Food-grade certified materials that are durable, safe, and compliant with current regulations.

- Easy installation and maintenance, as they are designed for intuitive use, with self-diagnostic systems and easily replaceable components.

Furthermore, all Mixtron brand solutions are customizable and available for various applications, from small food laboratories to large processing industries.

Choosing the right dosing pump for sanitization in the food industry is essential to ensure safety, efficiency, and regulatory compliance. By carefully evaluating the type of substance to be dosed, the required accuracy, compatibility with the existing system, and the necessary certifications, it is possible to identify the most suitable solution.

Relying on an experienced partner such as Mixtron means investing in reliable and innovative technologies that can optimize production and sanitization processes. Contact us to discover the perfect solution for your needs!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application