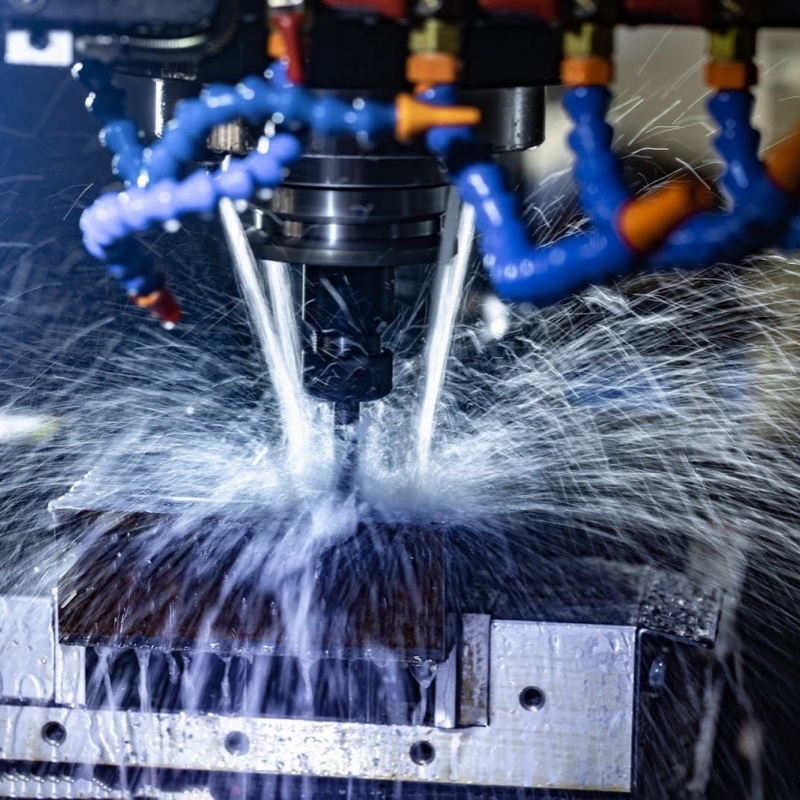

Industrial misting is a versatile technology that is increasingly used in a wide range of applications, from cooling large spaces to controlling humidity, from sanitising and disinfecting to treating odours and dust. The principle is simple: water is transformed into micro-droplets through high-precision nozzles powered by high-pressure pumps, generating a fine, controlled mist. However, the efficiency of the system depends largely on the choice of pump, which must be suitable for the application, the volumes required and the operating conditions.

Choosing the right pump means ensuring reliability, durability, optimised consumption and consistent performance over time. In this Mixtron guide, we will analyse the main technical criteria to consider when selecting a pump for industrial misting systems.

Criteria for selecting a high-pressure pump

Flow rate required

The first parameter to be evaluated is the flow rate, i.e. the amount of water (in litres per minute) that the pump is capable of delivering. This value must be sized according to the number of nozzles installed and their capacity, also taking into account any future developments of the system. It is always advisable to allow for a tolerance margin of 10–15% to compensate for pressure drops and ensure a useful reserve in case of system extensions or variable operating conditions. An undersized pump could compromise the effectiveness of the misting, while excessive oversizing leads to unnecessary consumption and greater wear.

Operating pressure

The operating pressure directly affects the quality of the atomisation: higher pressures generate finer and lighter droplets, ideal for applications such as evaporative cooling or humidification. Pumps in this particular sector typically operate between 60 and 120 bar, but it is essential that they are able to maintain this pressure constantly even under load. It is not enough for the pump to reach the maximum value indicated: it must be able to sustain it continuously. It is good practice to check that the nominal pressure of the pump is consistent with the specifications required by the nozzles and that the entire system (pipes, fittings, valves) is adequately sized to handle it.

Type of liquid used

Although in most cases the fluid used is simple water, in industrial applications it is not uncommon to use mixtures containing detergents, disinfectants or chemical additives. In these cases, it is essential to choose pumps made of compatible materials: ceramic pistons, stainless steel pump bodies and specific seals offer greater resistance to chemical attack and guarantee durability over time. The compatibility between materials and fluid is an aspect that should not be overlooked, especially for systems subject to frequent cycles or harsh environmental conditions.

Working cycle

The frequency and duration of pump use are another key criterion. If the system is intended to operate continuously, for example in 24-hour production processes or in environments with non-stop automation, it is essential to choose a pump designed for intensive industrial use. These pumps are equipped with adequate cooling systems, overheating protection and mechanical components sized to reduce wear. Conversely, for occasional or seasonal applications, models with less demanding duty cycles can be considered, thus also optimising the initial investment cost.

Ease of maintenance

Last but not least, the maintainability of the pump directly affects operating costs and the continuity of service of the system. It is preferable to choose models with easily accessible components, clear technical documentation and spare parts available at short notice.

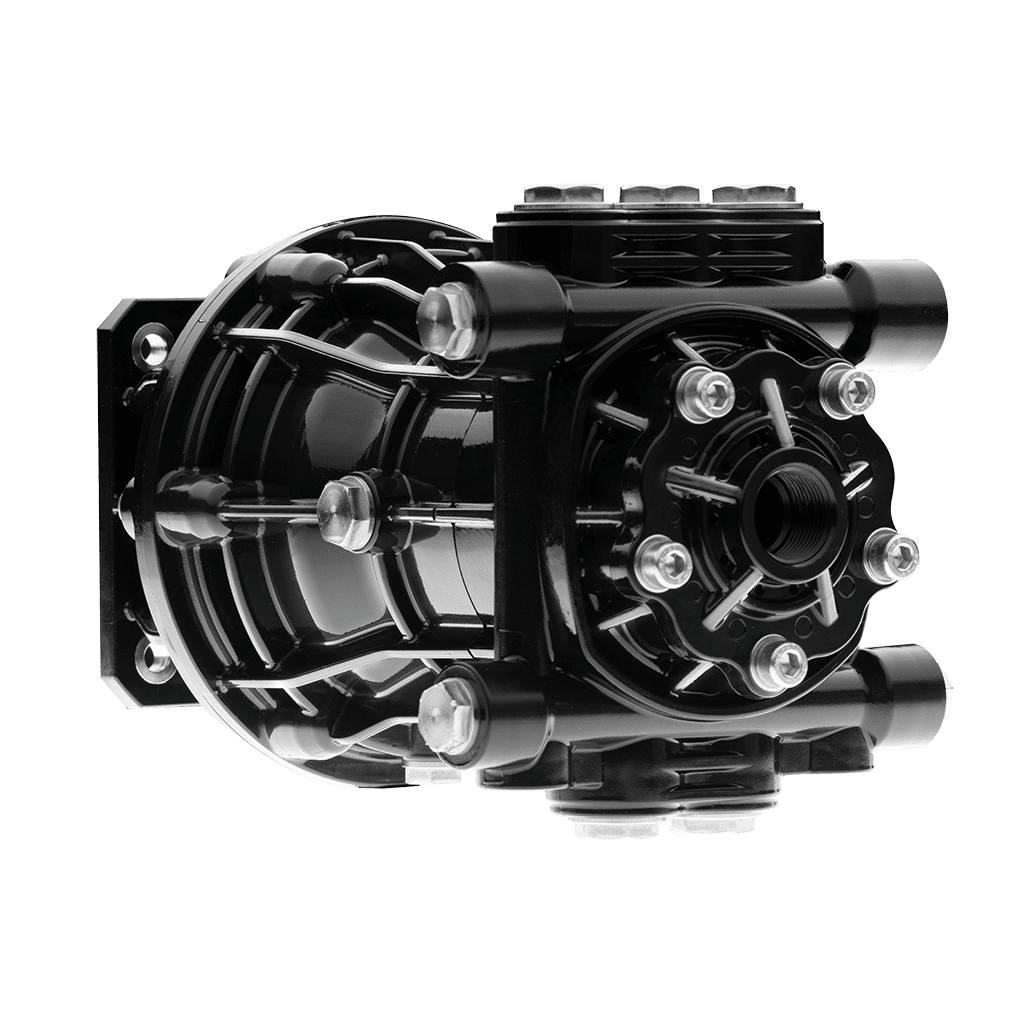

Mixtron's role in supplying high-quality high-pressure pumps

In the context of industrial atomisation, the quality and reliability of the high-pressure pump are crucial to the proper functioning of the entire system. Whether for cooling, sanitisation, dust control or humidification, Mixtron offers advanced technical solutions designed to deliver high performance, operational continuity and maximum precision in fluid management.

Mixtron's high-pressure misting pumps stand out for their consistent operating pressure, energy efficiency and robust materials, essential features for ensuring uniform misting, long service life and simplified maintenance. Each component is designed to ensure seamless integration with the system and to operate even in demanding environmental and operating conditions.

Choosing a Mixtron pump means optimising water and chemical consumption, improving air quality in industrial environments and ensuring the full effectiveness of cooling or treatment processes. With a constant focus on sustainability and ease of use, Mixtron is a benchmark for those seeking reliable, high-performance and durable solutions. Contact us now for more information!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application