Advanced technologies for industrial fire protection

Fire protection in industrial environments is of fundamental importance, not only for the safety of people, but also for the protection of property, equipment and operational continuity. Among the most innovative and effective technologies, water mist systems and traditional high-pressure pump systems represent two approaches that are as distinct as they are extremely effective in fighting fires in complex environments.

But what are the distinctive features of these technologies? And how do they fit into the landscape of industrial fire prevention solutions? Let's analyse their characteristics in detail to understand which approach may be most advantageous for specific protection needs.

Water mist extinguishing systems: innovation in fire suppression

Water mist extinguishing systems represent one of the most significant innovations in the field of fire protection in recent decades. Unlike traditional sprinkler systems, which release large quantities of water, water mist produces an extremely fine mist composed of millions of micro-droplets; thanks to their very high total surface area, these droplets interact with the fire in multiple and highly effective ways.

The principle of water mist extinguishing is based primarily on three mechanisms: cooling, inertisation (or displacement) and attenuation of radiant heat:

- Cooling occurs through heat absorption by water droplets that evaporate rapidly upon contact with the flames, drastically reducing the temperature of the fire.

- Inertisation occurs when the water vapour generated by the evaporation of the droplets displaces the oxygen in the fire area, smothering the flames;

- The attenuation of radiant heat is due to the mist's ability to block the thermal radiation emitted by the fire, protecting nearby structures and people.

Water mist systems offer numerous significant advantages: first, reduced water consumption compared to traditional systems, which translates into less water damage to equipment and products, reducing post-fire downtime. Secondly, the lightness of the system, due to smaller diameter pipes, simplifies installation and reduces structural loads. Furthermore, water mist is particularly effective on flammable liquid fires (Class B) and in confined spaces, where oxygen suppression is faster; however, its effectiveness can be affected by factors such as room ventilation and the presence of obstacles that prevent the mist from spreading evenly.

The selection and design of a water mist system requires careful assessment of the risk specifications, but its benefits in terms of protection and damage minimisation make it a cutting-edge solution for multiple industrial applications.

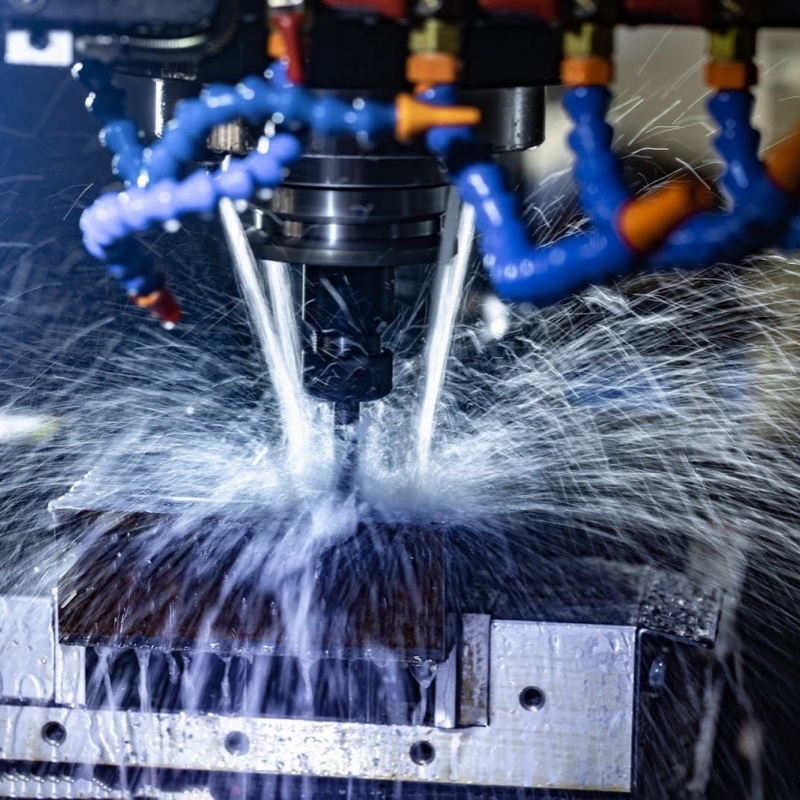

Fire-fighting systems with high-pressure pumps: the power of targeted water

Firefighting systems that use high-pressure pumps are the backbone of many traditional and modern protection strategies, especially when a large amount of extinguishing agent or strong penetration action is required. These systems are based on the delivery of water (or aqueous solutions) at high pressures through nozzles, lances or monitors, allowing the jet to be projected over significant distances and with considerable force.

High-pressure pumps are the heart of these systems, providing the flow and pressure required to fight large fires or protect large areas.

Typical applications for these systems include the protection of large warehouses, combustible material storage areas, petrochemical plants, power stations and critical infrastructure. The pumps can be powered by electric or diesel engines, ensuring reliability even in the event of a main power failure. Their robustness, combined with their ability to deliver large volumes of water, makes them particularly effective for cooling structures, protecting high-risk areas and containing large-scale fires. Although they use more water than water mist systems, high-pressure pumps offer immediate extinguishing capacity and versatility of use in different classes of fire. The efficiency of these systems is often linked to the availability of an adequate water supply and proper maintenance of the pumps and distribution networks, which must be able to withstand high pressures.

The use of high-pressure pumps is a well-established and reliable choice for many industrial risk scenarios, where the power of the water jet is a determining factor in fire suppression.

Water mist vs high-pressure pump systems: a comparison of the differences

A comparison between water mist systems and high-pressure pump systems highlights two different approaches to fire protection, both effective but with specific applications. Water mist is characterised by the use of extremely small amounts of water, capable of extinguishing flames through cooling, suffocation and thermal radiation shielding mechanisms. This technology is particularly suitable where it is necessary to limit water damage and preserve sensitive equipment, such as in technical rooms, data centres or confined spaces. On the other hand, high-pressure pump systems rely on the power of the jet and the availability of large volumes of water for their effectiveness, making them the most suitable choice for scenarios where fires can spread quickly and affect large areas, such as warehouses, large industrial plants and sites with high energy or chemical risks.

In other words, while water mist focuses on efficiency and reducing collateral damage, high-pressure pumps prioritise force, coverage capacity and immediate impact. The choice between the two systems therefore depends on the nature of the materials present, the configuration of the spaces and the level of protection required.

Choose Mixtron's industrial fire prevention technologies

Industrial fire prevention is a field in which the choice of extinguishing system is only part of a broader strategy that includes risk assessment, system design, staff training and ongoing maintenance. Both water mist and high-pressure pump-based systems make a fundamental contribution to this overall strategy. The choice between these technologies will depend on specific factors such as the nature of the materials present, the geometry of the spaces, the presence of personnel and industry regulations.

Mixtron manufactures high-pressure pumps that guarantee the precision required for water mist systems and the power and reliability needed for traditional high-pressure systems. With Mixtron, companies can count on robust, reliable and precise components, which are essential for the construction of fire-fighting systems that ensure maximum safety. Contact us for a personalised consultation!

You might also be interested in

Are you ready to experience innovation?

A wide range of cutting-edge technology solutions for any application